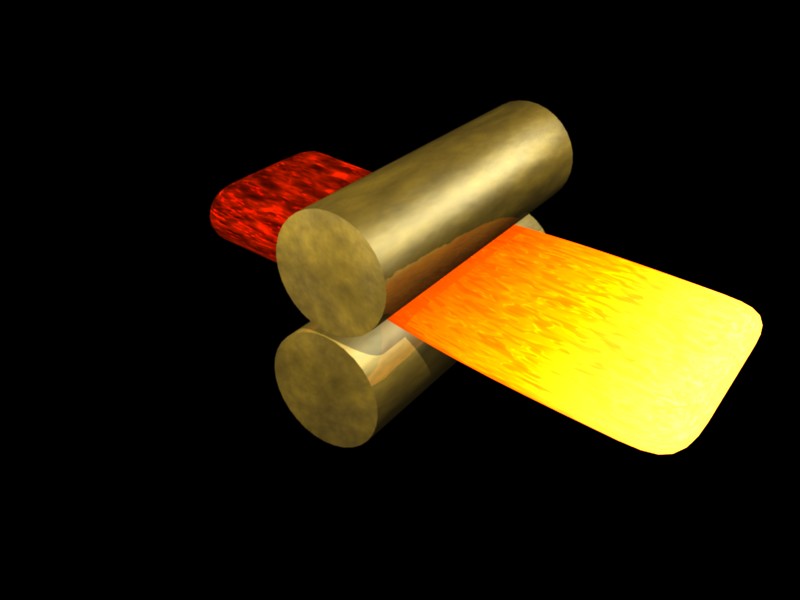

δικό μου έργο Own work, CC BY-SA 3.0

δικό μου έργο Own work, CC BY-SA 3.0 | Aspect | Hot Rolling | Cold Rolling |

|---|---|---|

| Metal Temperature | Above the recrystallization temperature | Below the recrystallization temperature |

| Work Hardening Effect | Generally does not show work hardening effect | Shows work hardening effect |

| Coefficient of Friction | Higher coefficient of friction | Comparatively lower coefficient of friction |

| Experiment Measurements | Difficult to make | Can be carried out easily |

| Reduction in Area | Heavy reduction possible | Heavy reduction not possible |

| Mechanical Properties | Improves properties by breaking cast structure and refining grain sizes | Increases tensile strength and yield strength |

| Rolls Radius | Generally larger in size | Smaller in size |

| Section Thickness | Very thin sections are not obtained | Thin sections can be obtained |

| Surface Finish | Metal oxide present, not a good surface finish | Smooth and oxide-free surface |

| Applicability | Used for ferrous and non-ferrous metals | Applicable to plain and alloy steels, non-ferrous metals, and their alloys |

| Sequence | Hot rolling is the father of the cold rolling. | Cold rolling follows hot rolling |

Labels:

Manufacturing processes