Користувач:Shkod, CC BY-SA 3.0

, via Wikimedia Commons

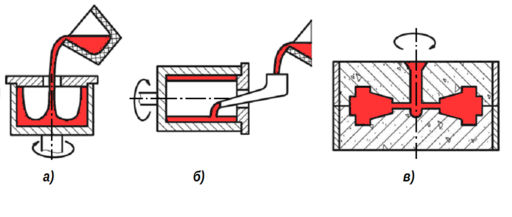

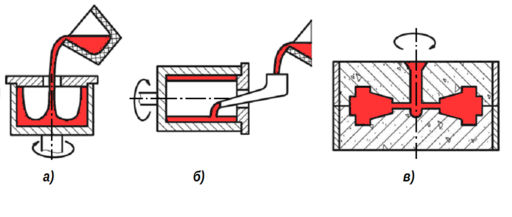

Centrifugal Casting

Centrifugal Casting

Centrifugal casting or rotocasting is a casting technique that is typically used to cast thin-walled cylinders. It is typically used to cast materials such as metals, glass, and concrete. A high quality is attainable by control of metallurgy and crystal structure. Unlike most other casting techniques, centrifugal casting is chiefly used to manufacture rotationally symmetric stock materials in standard sizes for further machining, rather than shaped parts tailored to a particular end-use.

Advantages

| Advantage |

| Relatively very light impurities move inwards towards center. So they can be removed easily thus helping in producing sound castings. |

| Gates and risers are not needed. |

| This technique is best suited for the mass production of symmetrical objects and Castings yield is very high in some cases it is even equal to 100%. |

| Castings acquire high density, high mechanical strength, and fine-grained structure. |

| Inclusions and impurities are lighter. |

| These castings have a directional solidification starting from outside to inside. |

Disadvantages

| Disadvantage |

| Skilled laborers are to be employed for this process. |

| An inaccurate diameter of the inner surface of the casting. |

| Only some shapes can be generated by this casting process. |

| Not all alloys can be cast in this way. |

| Centrifugal castings require very high investments. |

Applications

| Application |

| Bush bearings |

| Clutch plates |

| Paper making rollers |

| Piston rings |

| Cylinder liners |

| Pipes of water gas sewage |

Користувач:Shkod, CC BY-SA 3.0

Користувач:Shkod, CC BY-SA 3.0